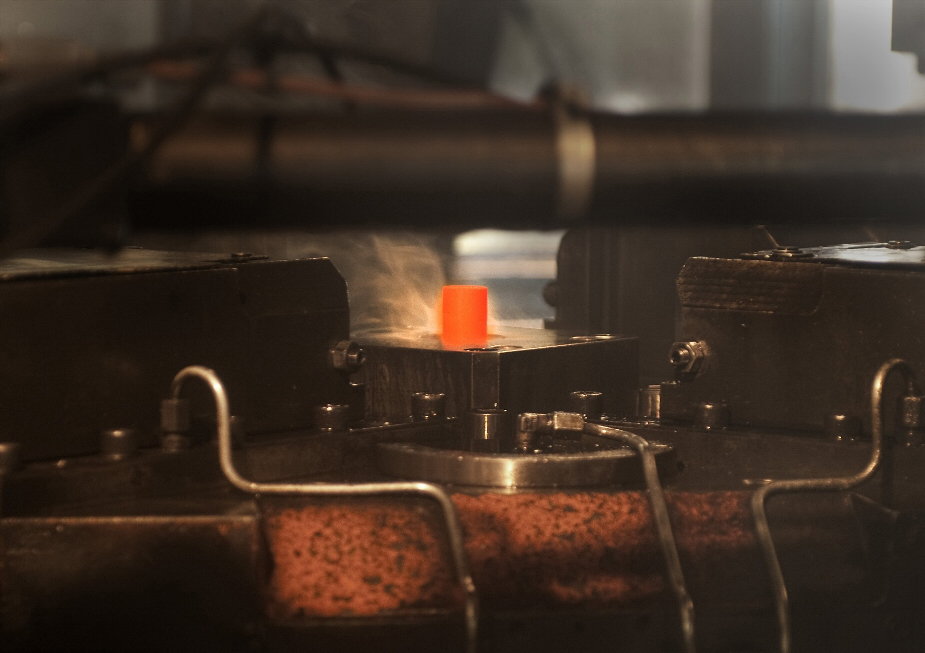

Hot pressing

If you compare hot pressing with traditional profile processing, there are many advantages, for example superior material savings, lower weight and less emissions. Tests have shown that hot-pressed products have superior material properties compared to other production methods.

Fast process

The material must be hot-pressed to the temperature where formability is optimal. It is then fed into the press tool and the tool halves press out the shapes of the part before it moves on for further processing.

The process itself is very fast with a cycle time of one to three seconds. The tools for hot pressing cost significantly less to produce compared to tools for other production methods. Hot-pressed goods become homogeneous and significantly minimize the risk of leakage, if, for example, components for liquids, air or gas that are exposed to pressure are being manufactured.